When inspecting swimming pool pumps, focus on safety (entrapment and electrical), basic operation under load, visible leaks, and obvious installation defects, and defer detailed performance or code compliance to a pool specialist.

Safety First

- Verify all pool equipment is on a clearly labeled disconnect you can operate without reaching over water or wet ground.

- Confirm GFCI protection is present for pump circuits and any nearby receptacles; note absence or tripping as a safety defect.

- Look for bonding conductors attached to metal pump parts and other metallic items (heater, rails, etc.) near the pool; report missing or loose bonding.

- Do not remove covers or reach into wet equipment areas you are not trained to service; limit yourself to normal homeowner-access panels and lids.

Running and Observing the Pump

- Turn the pump on near the start of the pool portion of your inspection and let it run at least 20–30 minutes while you inspect other areas.

- Listen for abnormal noise: loud grinding, screeching, or rattling can indicate failing bearings or cavitation; recommend further evaluation.

- Watch the pump strainer pot: it should fill solidly with water within a couple of minutes; if it will not prime or runs dry, shut it off and recommend service.

- After circulation has been going 10 minutes, persistent air bubbles in the basket or in the return flow suggest a suction-side leak you should note.

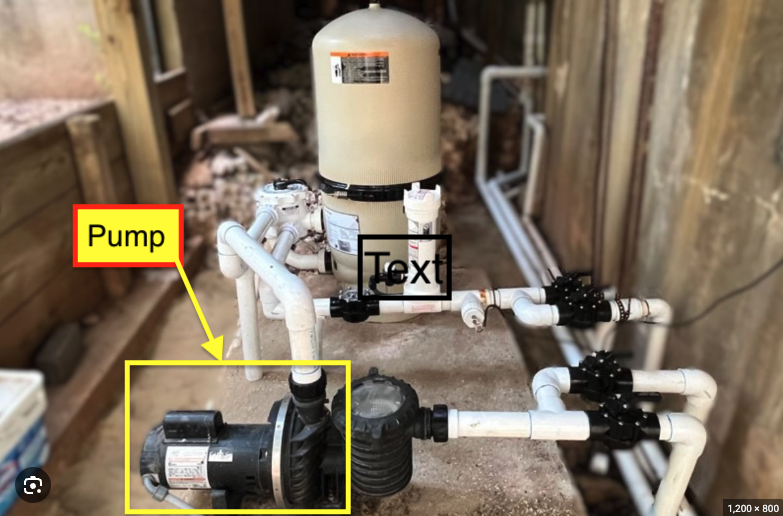

Visual Checks at the Pump

- With power off at the disconnect, inspect the clear lid and pump housing for cracks, crazing, or signs of prior leakage or repairs.

- Open the pump basket lid (if safe to do so) and check the basket for damage, missing sections, or heavy debris accumulation; note if the lid O-ring is deteriorated or missing.

- Scan around the pump base and unions for active leaks, corrosion, or mineral/staining that indicates chronic leakage.

- Look at the motor shell and wiring compartment for rust, damaged conduits, open knockouts, or non-listed wiring methods.

System and Standards Awareness

- Confirm there is at least one skimmer or suction source in use and that visible drain covers in the pool or spa are present, secure, and listed anti-entrapment types; missing or broken covers are a serious hazard.

- Note if the pump appears undersized or oversized for a large pool, or if it is an older single-speed unit; for energy-efficiency and TDH/flow compliance with current ANSI/PHTA/ICC-15 and DOE rules, recommend evaluation by a qualified pool contractor rather than attempting to size it yourself.

Reporting Approach for Home Inspectors

- Clarify in your agreement and report that you perform a limited, visual, operational check of accessible pool equipment, not a code-compliant or leak-detection certification.

- Call out: lack of GFCI, missing/loose bonding, leaks at pump or piping, failure to prime, abnormal noise, damaged housings/lids/baskets, missing or non-compliant drain covers, and any DIY or unsafe wiring at the pump.

- For anything beyond a basic visual and functional check—such as hydraulic calculations, TDH/pressure verification, internal pump condition, or full compliance with the ISPSC—recommend further evaluation by a licensed pool professional.