Check the following:

Improper Locations

Furnaces should not be located in bedrooms, bathrooms, or storage closets

Adequate combustion air:

Combustion appliances require 50 cubic feet per 1000 BTU per hour (BTU/h) aggregate input. "Aggregate" means that if two combustion appliances such as a gas-fired furnace and a gas-fired water heater are installed in the same room, each of their input ratings in BTU/h must be included when calculating adequate combustion air.

Gas supply for:

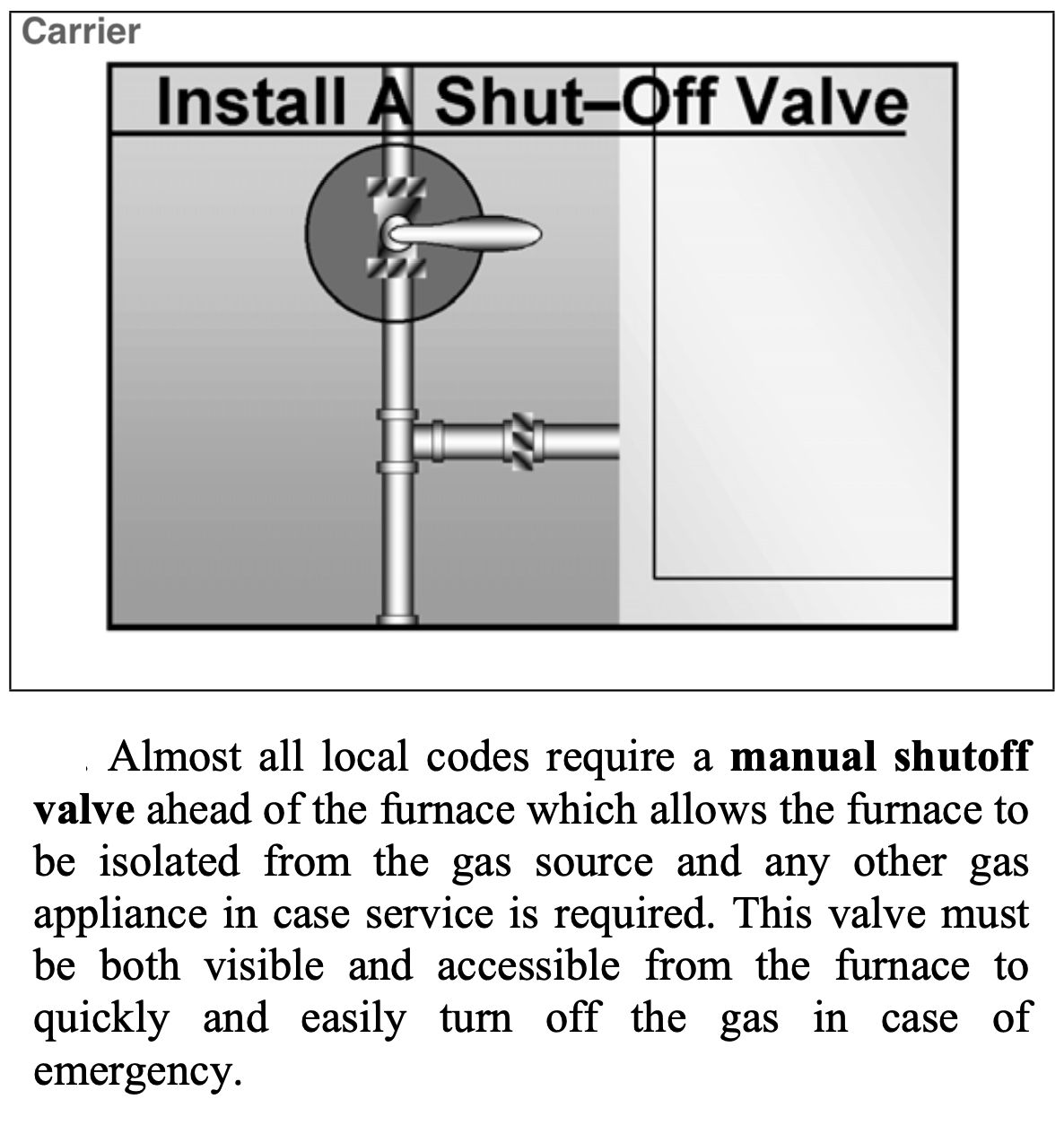

- Shut off installed near the furnace

- Union installed between shut-off and furnace

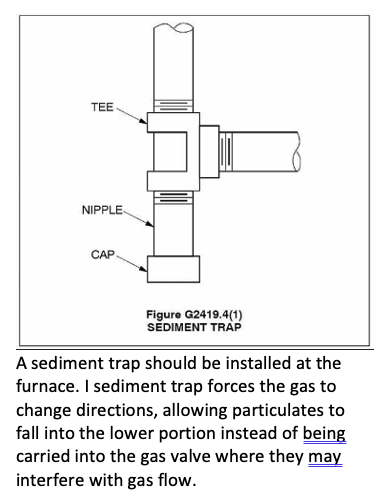

- Sediment trap/drip leg installed

- Proper gas supply piping

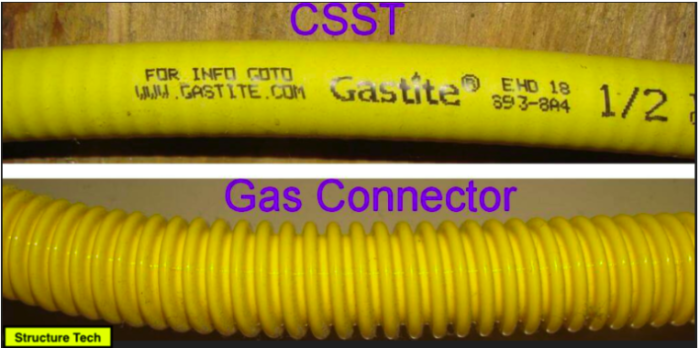

- Acceptable materials are black steel, corrugated stainless steel tubing (CSST), and copper, although permissible copper varies by jurisdiction and may be limited to certain types.

Flex (appliance) connector:

Flex connectors are maximum 3 feet (or 6 feet depending on jurisdiction) for furnaces and must have a shutoff where it connects to rigid gas piping. Flex connectors cannot pass through walls, floor, or ceilings, and cannot be concealed. Flex connectors may be required in areas subject to earthquakes.

Avoid confusing CSST with appliance connectors

Combustion exhaust venting

- Vent material (plastic means high efficiency)

- Vent connector proper slope (1/4” per foot)

- If the furnace and a water heater connect to the same vent, the water heater should connect upstream from the furnace.

- If the furnace and a water heater connect to a chimney, the water heater should connect above the furnace, and a cleanout should be installed within 6” below the furnace vent connector.

Also:

- Presence of a kill switch.

- Presence of a humidifier

- Ducts

- Type?

- Sealed?

- Insulated?

- Securely attached

- Note the filter type (electronic/fabric), location and condition

Furnace Inspection Process

- Shut off the furnace at the kill switch

- Remove the access covers

- Note dirt, debris, and corrosion

- Photograph the manufacturer’s label/ data plate

- Examine the burn chamber

- Scorching

- Corrosion

- White residue

- Loose or damaged burners

- Examine the blower compartment

- Dirty or greasy buildup on the blower vanes

- For high efficiency furnaces, check for proper condensate discharge.

- Corrosion resistant piping (ABS, PVC, CPVC, copper, (not coiled tubing) PEX, polyethylene, polypropylene).

- ¾” minimum

- Condensate pumps appear to be in satisfactory condition with proper electrical connections (not extension cord)

- Trap are installed in condensate lines as required by the manufacturer.

- Horizontal runs must slope minimum 1/8 inch per foot

- Condensate must discharge to an approved location. Not a street, alley, or sidewalk. Check locally for “approved locations”. Most discharge to floor drains.

- Furnaces in attics must have a drip pan with overflow and condensate discharge to an approved location.

- Turn the thermostat up high

- Turn the furnace on at the kill switch

- Watch for proper operation. You may need to depress the access cover safety switch for the furnace to operate.

- The burners will ignite and run for a short time before the blower activates. Watch for any change in the flame when the blower activates. Changes in the flame can indicate a cracked heat exchanger. Recommend service. Flame color should be blue. Yellow or white flame indicates a need for service.

- Listen to the blower. Any unusual noise indicates a need for service.

- Check temperatures at registers with a digital thermometer. Comment on any that are significantly hotter or colder than the rest.

Click the arrow in the upper left corner to download