Water Heaters: 2021 IRC Chapter 5

- ICC Water Heater Safety This 3-page article from the ICC lists 13 common problems that inspectors can expect to encounter with water heaters. Illustrations and explanations are clear.

- TPR Discharge Pipe Regulations

- Backdrafting: Causes and Recognition

- Inspecting Water Heaters 18-page article on inspecting water heaters.

- Seismic Bracing of Residential Water Heaters 12 page article on securing water heaters in seismic zones.

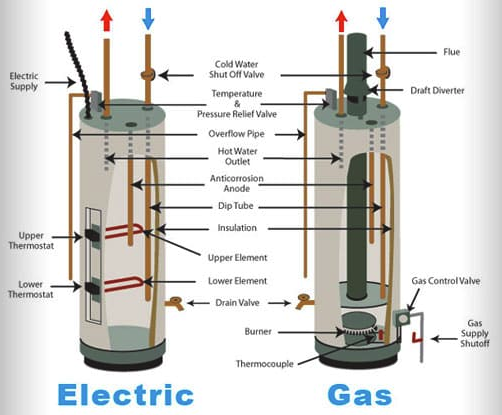

- Inspecting Electric Water Heaters

- Using information from the Building Intelligence Center you can use a serial number to determine the date of manufacture for the water heaters.

General:

- Response to the demand for hot water

- Describe as gas, electric, or tankless (if gas WH is tankless, recommend service);

- General exterior condition;

- Seismic straps where necessary;

- Drain pan w/overflow pipe needed where tank leakage may cause damage. Overflow pipe must be the same material as hot water distribution pipes and terminate at a floor drain or indirect waste receptor (not in a waste pipe. It may terminate outside at between 6" and 24" above grade.

- Recommend anode rod replacement? (deterioration rate depends on water composition).

Improper Locations:

- Gas water heater should be located minimum 10 ft. from return air vent

- Not allowed in bathrooms or storage closets (especially bedroom closets).

- If in garage, must be on 18-inch minimum height platform, unless FVIR (Confirm with local codes).

Data Plate

- Manufacturer

- Serial number

- Tank capacity

- Year of manufacture (comment if past warranty)

Recording/photographing data plate information is a good idea. Unscrupulous sellers have been known to remove a newer water heater and install an older one after the inspection is complete.

Find water heater date of manufacture here!

Shut-offs:

- Cold water shut-off installed within arm's length

- Gas shut off installed

Fuel supply:

- Flex gas pipe max. 36" with gas shut-off valve;

- Sediment trap (makes gas flow change direction) installed between the gas shut-off and the gas valve;

Check fittings for gas leaks

- Combustible gas detector

- Soapy water solution

- Your nose

Temperature/Pressure relief (TPR) valve and discharge;

Discharge pipe defects:

- None installed;

- Terminates more than 6 inches above floor;

- Termination capped;

- Termination threaded;

- Termination not readily visible;

- Terminates in drip pan;

- Terminates outside;

- Terminates in crawlspace;

- Restricted termination;

- Smaller diameter than TPR valve outlet;

- Connected to plumbing waste pipe;

- In-line pump installed;

- Trap installed

- Improper pipe material; or

- 1 discharge serves multiple TPR valves.

- Does not discharge through an air gap located in the same room as the water heater.

ACCEPTABLE TPR DISCHARGE PIPE MATERIALS

Although what is acceptable can vary by jurisdiction, the following materials are listed in the 2015 International Plumbing Code as being acceptable for TPR discharge pipe:

- Brass pipe;

- CPVC;

- Copper or copper-alloy tubing (Types K, WK, L WL, M, or WM);

- PEX;

- High-density PEX (PEX-AL-HDPE);

- Ductile iron pipe;

- Galvanized steel pipe;

- Polyethylene/aluminum/ Polyethylene (PE-AL-PE) composite pipe;

- Polyethylene of raised temperature (PE-RT) plastic tubing;

- Polypropylene plastic pipe or tubing;

- Stainless steel pipe (types 304 or 304L)

- Stainless steel pipe (types 316 or 316L)

Notes:

-

- PVC is not acceptable.

- If the discharge pipe is a flexible material, some method should be used that will hold the termination in place during discharge.

Combustion Air Requirements:

There is no one simple formula for calculating adequate combustion air. Calculations must be adjusted for homesite conditions. Unless you're sure about conditions, I suggest you describe the presence of any combustion air supply ducts, say- at the most- that it appears to be enough or insufficient, and disclaim if there's any doubt.

Formula:

Combustion appliances require 50 cubic feet per 1000 BTU per hour (BTU/h) aggregate input. "Aggregate" means that if two combustion appliances such as a gas-fired furnace and a gas-fired water heater are installed in the same room, each of their input ratings in BTU/h must be included when calculating adequate combustion air.

Look here for a more detailed explanation.

Combustion Chamber:

- Flammable Vapor Ignition Resistant (FVIR) type water heaters required since 2003.

- Blue flame desirable, red or yellow flame recommend service

- Rust flakes on chamber floor indicate tank deterioration

- Proper chamber cover

- Soot/carbon on exterior above chamber?

Combustion Exhaust Venting

- Proper draft diverter

- B vent

- 1-inch clearance to combustibles

- Adequate slope (1/4-inch per foot)

- Joins shared vent stack above furnace or boiler vent

- Vents into unsealed brick chimney? (defect)

- Backdrafting? With other combustion appliances operating?

- Corrosion/white powder indicated moisture problems (possible inadequate draft)

- Gas combustion exhaust vent termination heights

- White residue on combustion vents

Signs of Backdrafting:

- Melting or distortion of plastic escutcheons where hot and cold pipes penetrate the top of the water heater.

- Corrosion on top of tank (white or rust-colored).

- Moisture on top of the tank.

- Heavy condensation on the cold-water pipes in the room.

- Improper slope or excessively sharp turns of the combustion exhaust vent.

Testing for backdrafting:

- Turn down the thermostat if the furnace or boiler shares the exhaust vent;

- Close all doors and windows;

- Close any open fireplace dampers;

- Turn on all kitchen, bathroom and laundry room exhaust fans;

- Turn on the clothes dryer;

- Run the hot water long enough to activate the water heater burner;

- Backdrafting will fog a camera lens & you can feel it on your hand.

Water Pipes:

- Corrosion on fittings;

- Make sure connects are not reversed;

- Cold water shut-off within arm’s length;

- Electrical bonding and jumper between hot and cold pipes;

- Combustible material clearance from exhaust flue;

- Cold water supply pipe soldered directly to cold water inlet may damage dip tube or tank.

Expansion tank:

Check your jurisdiction, may be required on newer systems.

Hot Water Re-circulation System

Comment if installed and whether it's working (short wait for hot water at fixture furthest from water heater).