Watch for the following in conventionally framed roofs:

- Sagging ridge/rafters;

- Damaged framing;

- Poor design/materials/workmanship;

- Adequate wood to wood connections (fit/hardware/fasteners);

- Toe-nailed rafter plumb cuts: 3 in one side, 2 in the other;

- Proper metal connector fasteners: (tico nails #10 not #8), no 8d checker-head sinkers/roofing nails;

- Nails, not screws;

- Collar ties: in roof upper 1/3, every other rafter pair (Not needed where metal connectors are used at the rafter/ridge connection. Their purpose is to resist uplift;

- Rafter ties: as low as possible, every other rafter pair;

- 5-16d nails through the tie into the rafter;

- Rafter ties continuous across the attic (or adequately fasted where they overlap);

- Purlin braces: bear on walls, not ceiling joists; or

- If purlin braces bear on strongbacks (or ceiling joists), check for ceiling sag.

Metal Connectors and their Fasteners:

- Fasteners for almost all single metal connectors will be minimum 10d nails with the number marked on the nailhead (not 8d).

- When hangers do not support top chords laterally, i-joists require web stiffeners to be installed.

- The Simpson Strong Tie catalogue for framing connectors lists fastening requirement for most connectors you're likely to encounter.

CONVENTIONAL RIDGES

Are Ridge Boards Necessary?

Encountering older roofs without a ridge board is common. Typically, these roofs are associated with wood board sheathing.

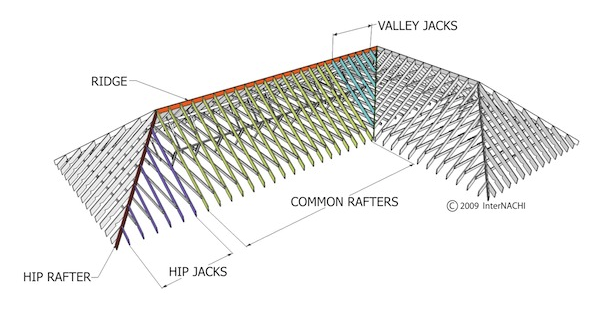

On roofs with modern panel sheathing, the sheathing on a single slope acts to a great extent as a single diaphragm. Backing for perimeter nailing is provided by sub-fascia at the eaves, by common, hip, or valley rafters at the gables, hips, or valleys, and at the peak, backing is provided by the ridge board.

On older roofs with wood boards used as sheathing, the sheathing acts less as a diaphragm, and so perimeter nailing is less important. On these houses, the ridge is often 1x6 and its main purpose is to provide backing for nailing rafters, especially if rafters on opposite sides of the ridge to not exactly oppose.

Why Rafters Pairs Should Oppose

Opposing rafters form pairs that need to have their bottoms tied together in order to form a simple triangular truss. To be structurally efficient and allow rafter ties to effectively connect their bases, rafters need to oppose each other as directly as possible.

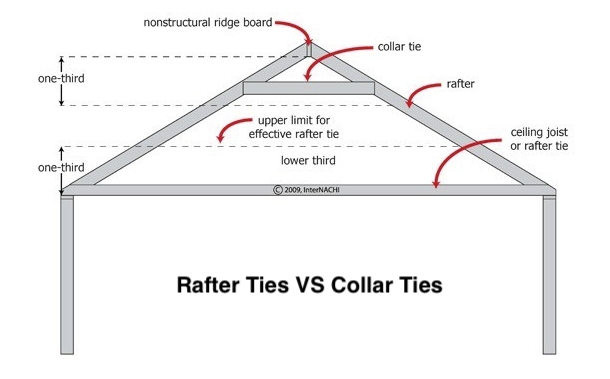

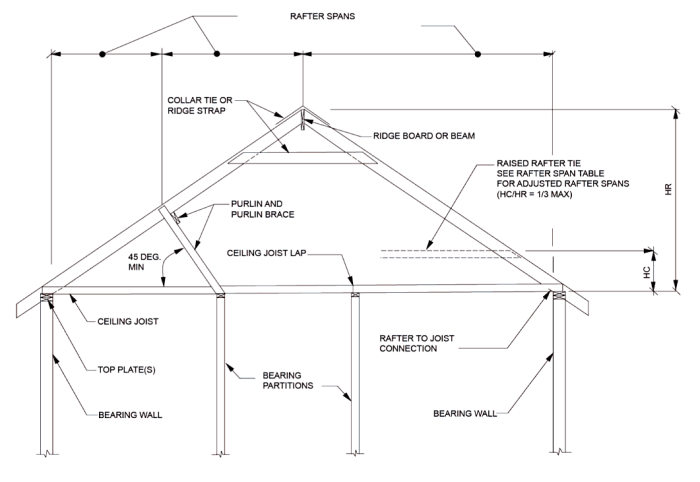

Collar Ties VS Rafter Ties:

COLLAR TIES are installed to resist uplift. They're typically installed in older homes in which rafters are not fastened to the ridge with metal connectors (hangers). Where they are required, they are usually 1x6 or 2x4, typically installed every other rafter pair (4 feet on center), in the upper third of the roof. 5 nails per side.

RAFTER TIES are required on all conventionally framed roofs unless a structural ridge (scroll down) is installed. They should be installed as low as possible in the roof. Min. per side: 5 face nails into the rafter and 1 toenail into the top plate (when possible). Ceiling joists almost always serve the function of rafter ties.

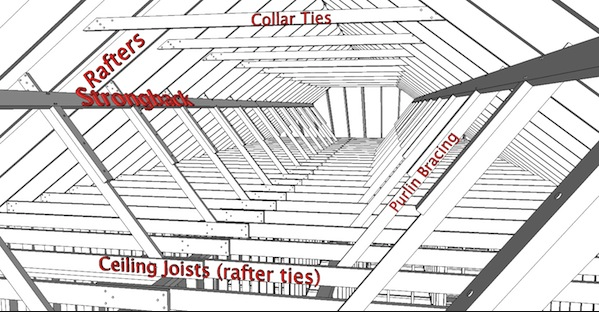

Purlin Systems

Where rafters are over-spanned and likely to sag, the span can be reduced by installing a purlin system. Purlin systems are part of the load path that transfers the roof load to the underlying structural elements.

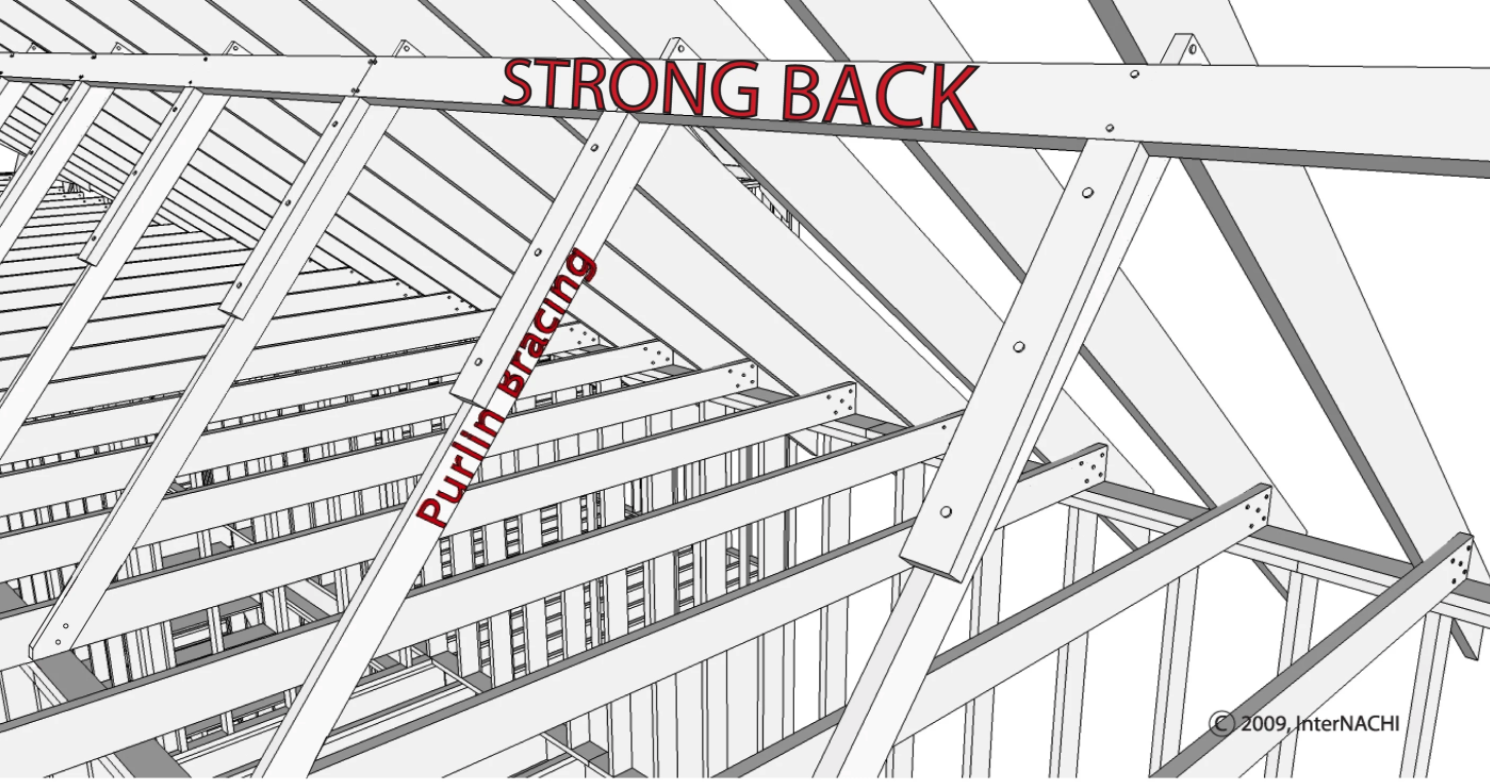

Purlin Strongbacks

A purlin system consists of a strongback that rests against the undersides of the rafters. Modern building codes require strongbacks to be at least the same dimension as the rafters, but this is a relatively recent requirement. Many, many purlin systems have been installed with strongbacks that don't comply with this provision with no problems resulting at all. If you feel compelled to mention it at all you should mention in your narrative whether you see signs of failure due to failure to comply with this provision.

Purlin Bracing

Strongbacks are supported by braces that should angle no more steeply than 45 degrees. They should rest on top of bearing walls. Nailing patterns are:

- Through the brace into the rafter: 5- 16d

- Through the strongback into the brace: 2- 16d

- Through the brace block into the brace: 3- 16d

- Toenails into the top plate: 2-16d

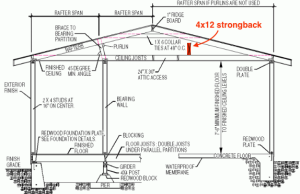

Ceiling Joist Strongbacks

Occasionally, when no bearing wall is handy, purlin braces will bear on ceiling joists. Look for sagging ceiling joists and when you see them, mention that this condition is improper and will worsen over time if not corrected. To alleviate this condition, a ceiling joist strongback is sometimes installed across the tops of the joists to prevent sagging.

Shown above, a 4x12 beam is used as a ceiling joist strongback. The beam would bear on top of walls at both ends and be connected to ceiling joists with metal connectors.

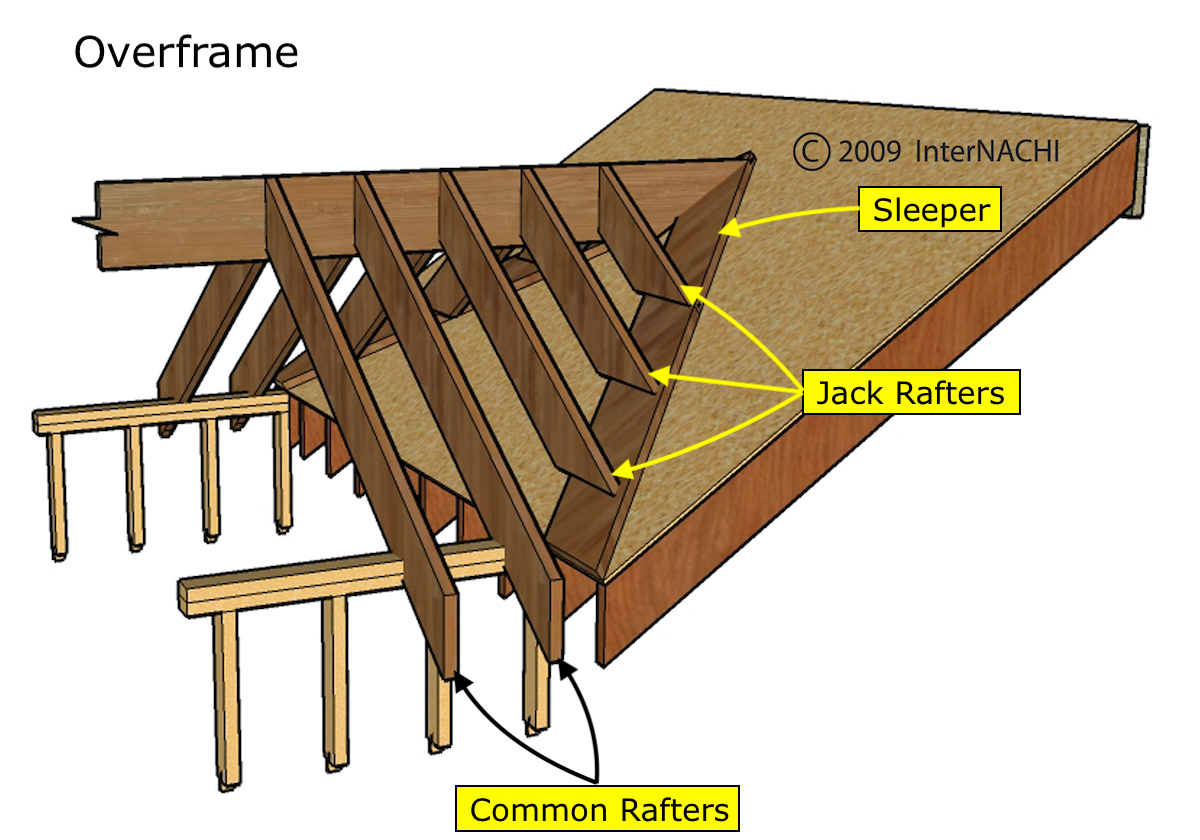

Overframes

This condition is most commonly seen where a garage roof intersects the slope of a house roof. To simplify the framing intersection, an overframe is typically installed.

Concerns:

The overframe ridge should align with the rest of the garage roof, appearing as a straight line for the entire length of the ridge.

The bottom cuts of the jack rafters should fully bear on a 2x board (size depends on jack rafter size) called a "sleeper". Jack rafters should not bear directly on the roof sheathing.

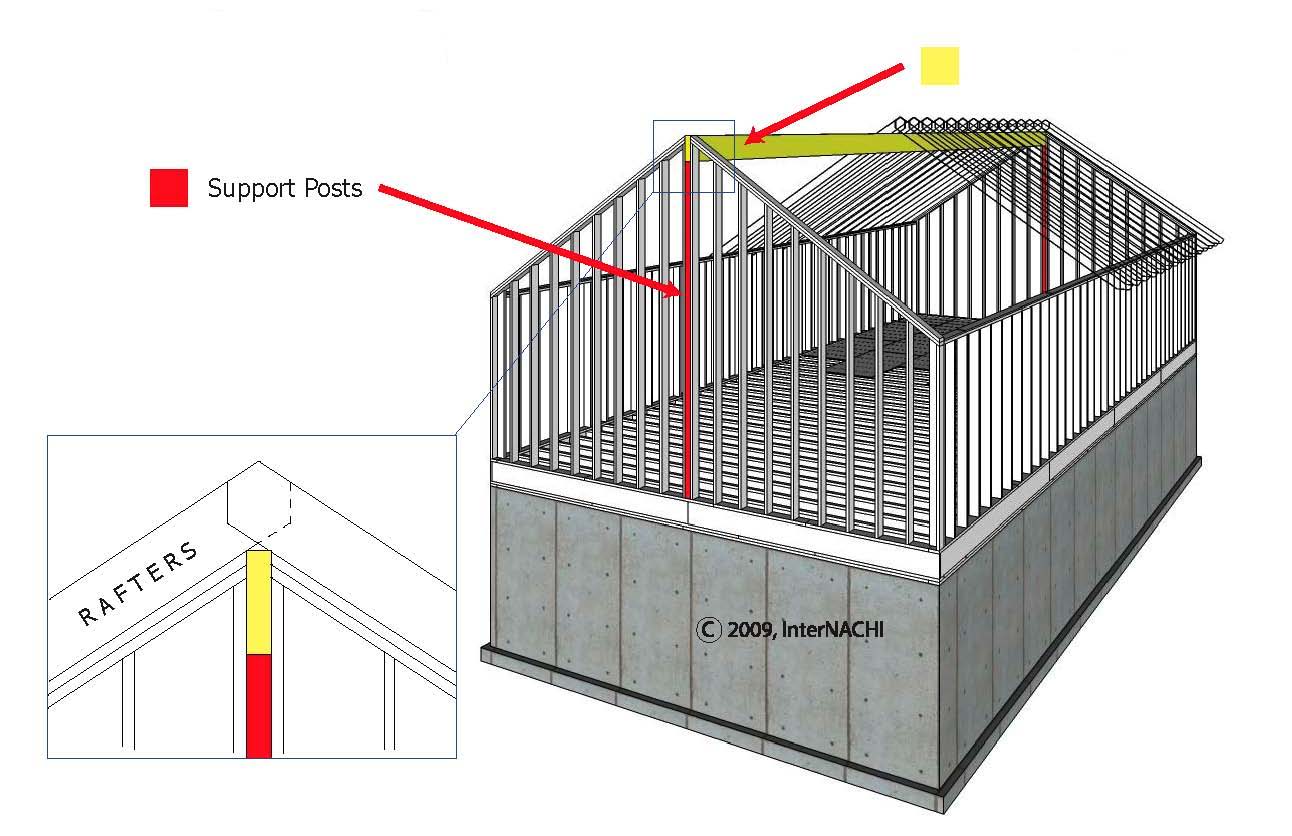

Structural Ridges

A structural ridge is typically used in a part of a home with a cathedral ceiling. There are no rafter ties installed to keep the walls from spreading and the ridge, which is supported by posts at both ends (and sometimes at intermediate locations if it’s a very large room) must support half of the entire roof load without sagging. The other half of the roof load is still transferred to the exterior bearing walls.