Photos

- Photograph all roof slopes. This is for reference. Include at least one in your report. Photos taken from low, looking up, or photos taken across the roof, are better than photos taken from the ridge.

- Take photos of roof sections approx. 2’x3’ that show the average condition of the roof. If it varies with roof slope, shoot however many you need to record the different conditions.

- Photograph examples of defects (including sealant instead of flashing). Newbies tend to shoot too close. You need to be back far enough for visual reference but close enough to see the defect details.

- Hold the camera horizontal or vertical, don’t tilt to the angle of the roof.

Installation

- Minimum roof slope: 3&12 (IRC), 4&12 (NRCA);

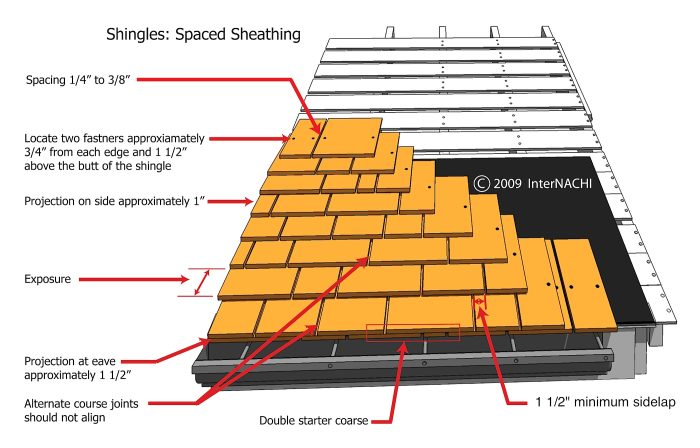

- Spaced sheathing should have no underlayment;

- Solid sheathing

- Underlayment

- 1 layer #30 (NRCA

- None (CSSB)

- No interlayment allowed;

- Spacing between shingles in the same course:

- 1/4-inch to 3/8-inch.

- Minimum shingle width: 3 inches ;

- Minimum sidelap 1 1/2 inches ;

- Joints in less than 10% of shingles should align in alternate courses;

- In lower quality shingles, the centerline of the heart should be offset 1 1/2 inches from vertical joints in adjacent courses.

- The starter course should be doubled or tripled;

- Overhang at eve: 1 1/2 inches;

- Overhang at rake: 1 inch - 2 nails per shingle only, 3/4-inch in from edges, 1 1/2 inches above exposure line.

- Hot dip galvanized nails only, no electro-galvanized! Stainless steel within 15 miles of salt water;

Weather Exposure for #1, #2, and #3 wood shingles

3&12 pitch to 4&12:

#1 #2 #3

16": #1- 3 3/4" #2- 3 1/2" #3- 3"

18": #1- 4 1/4" #2- 4" #3- 3 1/2"

24": #1- 5 3/4" #2- 5 1/2" #3- 5"

4&12 pitch or greater:

16": #1- 5" #2- 4" #3- 3 1/2"

18": #1- 5 1/2" #2- 4 1/2" #3- 4"

24": #1- 7 1/2" #2- 6 1/2" #3- 5 1/2"

Condition

- Cupped or curled shingles

- Splitting

- Erosion

- Missing shingles

- Loose shakes

- Biological growth

- Exposed fasteners

Flashing

- All sidewall flashing should be step flashing EXCEPT! In areas designated “high wind” (Broward, Miami-Dade counties in FL), continuous flashing may be required by the AHJ.

- Counter-flashing properly installed.

- Proper penetration flashing

- Plumbing vent pipes: proper installation and rubber boot condition.

- Combustion vents

- Attic ventilation devices should have screens.

- Dryer vent

- HVAC intake and exhaust

- Misc. vents (bathroom, laundry exhaust fans, etc.)

- Chimney flashing and counter-flashing

- Valley flashing

- Identify type of valley (open or closed)

- Comment on any roll roof open valley linings

- Check the potential for cross-wash.

- Kickout flashing with sealant.

- Roof-edge flashing

If you can’t/don’t walk the roof:

- Get photos of as many slopes as possible. You can see more of the roof from farther away. Rest your camera on/against something stable and zoom in.

- Get medium and close-up shots however you can.

- View the roof from a ladder at the roof edge, other parts of the home, hillsides or any other vantage point you can find.

- Try using binoculars even from the roof edge.

- Consider using a telescopic pole to take photos of portions of the roof that are difficult to see. Some inspectors are now using drones with cameras attached.

Aging/Failure Characteristics

Curling: Some shingles will curl over time and curling often appears in patches on the roof, indicating that some shake bundles are made up of shingles predisposed toward curling. Curling seldom causes leakage.

Cupping: Wood shingles are also subject to cupping, meaning they curl across their width instead of across their length.

Splitting: As time passes, moisture cycling will cause shingles to develop splits. Small cracks appear first at the tips of butts and over time propagate upwards, eventually developing into splits that extend clear through the shake along its length. A split caused by natural weathering will be the same color as the rest of the shingles, typically greyish brown, and will have smooth, rounded over edges.

A split with causes other than natural weathering, like hailstrikes, will be orange in color and will have sharp edges.

Erosion: Erosion it typically caused by flowing or dripping water. The source may be an overhanging gutter or downspout, or even runoff falling from the butt of an overlying curled shake.

Decay: Decay typically develops first in shake butts, since this is the thickest part of the shake and holds moisture like a sponge.

Displacement: Over time, thermal cycling causes metal fasteners to expand and contract. This enlarges the holes in both the wood shingles, and in the substrate to which they are fastened. At the same time, moisture cycling causes shingles (and eventually the substrate) to expand and contact further degrading the connection between fasteners and wood. This overall degradation of the fastener connection reduces the resistance of the roof to wind damage.

Ridge and hip cap shingles are typically the first to be lost, followed by field shingles near the roof corners and ridge.

Roof Sheathing

Solid sheathing: Solid sheathing can be used under shingles and may be required in areas subject to seismic activity or when treated shingles are used.

Spaced sheathing: Shingles can be applied over spaced board sheathing with boards installed on centers to match the shingle exposure. 1x4 is the minimum size. Where 1x4 is used on 10-inch centers, an additional 1x4 should be installed between sheathing boards. 1x6 is acceptable. In most places, in newer construction the maximum gap allowed between boards is 3 1/2 inches. The distance from centerline to centerline of the sheathing boards should match the weather exposure of the shingles.

In most jurisdictions, in newer construction the maximum gap allowed between boards is 3 ½ inches.

The distance from centerline to centerline of the sheathing boards should match the weather exposure of the shingles.

In humid climates, the CSSB recommends installation of a rainscreen system. This consists of shingles fastened to 1x4 or 1x6 horizontally-oriented battens installed over vertically oriented 1x4 counter-battens installed over solid sheathing.

Underlayment, Rainscreen, and Ice Barrier

Roofing felt can be installed over either solid or spaced sheathing. Wood shingles are installed at an exposure that creates a triple-thick layer of shingles over the entire roof. Key to a long service life is fast drying of wood shingles. Anything that lengthens drying time will shorten service life.

Spaced sheathing:

- Both the National Roofing Contractor’s Association (NRCA) and the Cedar Shake and Shingle Bureau (CSSB) recommend that no underlayment be installed when wood shingles are installed on spaced sheathing.

Solid sheathing:

- The National Roofing Contractor’s Association (NRCA) recommends installation of a single layer of #30 felt underlayment.

- The Cedar Shake and Shingle Bureau (CSSB) recommends that pressure treated shingles be used when shingles are installed over solid sheathing.Or

- Especially in humid climates, the CSSB recommends installation of a rainscreen system. This consists of shingles fastened to 1x4 or 1x6 horizontally-oriented battens installed over vertically oriented 1x4 counter-battens installed over solid sheathing. Counter-battens should be located directly above rafters or trusses. Counter-battens should be located directly above- and fastened to- rafters or trusses.

Ice barrier;

Where the average January temperature is 30° F or less (25° F in some jurisdictions), or in areas subject to ice dam development, some jurisdictions require an ice barrier to be installed over solid sheathing. An ice barrier typically consists of self-adhering, self-sealing, waterproof underlayment installed from the roof edge to a point 24” inside the exterior wall (measured level). The balance of roof sheathing may be solid or spaced sheathing.

SHINGLES SHOULD NEVER HAVE INTERLAYMENT INSTALLED!

Flashing

- Sidewall conditions should have step flashing.

- Valleys should be lined with #30 felt under metal.

- Valley flashing width minimum less than 12:12: 22 inches.

- Valley flashing width minimum 12:12 or steeper: 16 inches.

All flashing installed should be installed in a manner that will keep runoff on the surface of the shingles.

Types of Wood Shingles

Wood shingles are available in the following types:

#1- These top-grade shingles are 100% heartwood, 100% clear and 100% edge grain. Available in 16" or 18" or 24" lengths.

#2- A good grade for many applications. Not less than 10" clear on 16" shingles, 11" clear on 18" shingles and 16" clear on 24" shingles. Flat grain and limited sapwood are permitted in this grade.

#3- A utility grade for economy applications and secondary buildings. Not less than 6" clear on 16" and 18" shingles, 10" clear on 24" shingles.

Making Recommendations

Always recommend a qualified roofing contractor for repairs, corrections or maintenance, and make sure your client knows that all roofing contractors will not be qualified.