The following installation guides can be used as reference for inspecting manufactured stone veneer:

Installation Guide to Adhered Manufactured Stone Veneer from the Masonry Veneer Manufacturer's Association

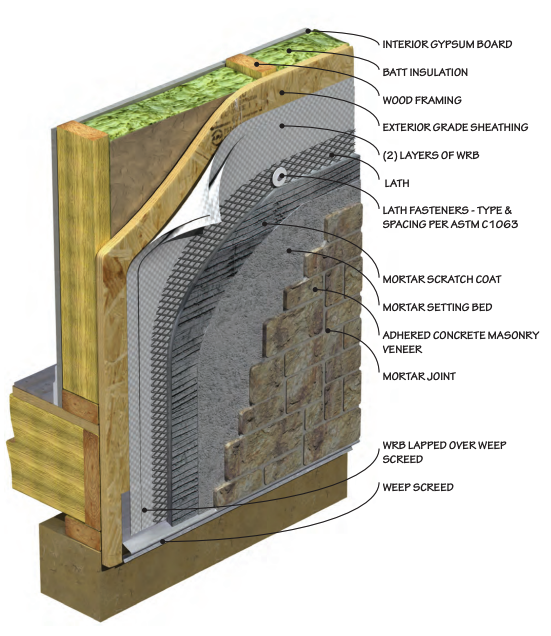

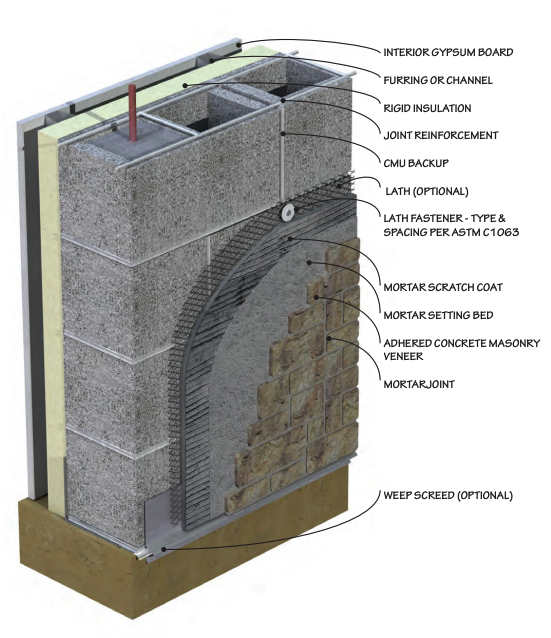

Installation requirements vary with substrate type. You may be able to view the substrate by looking up from the underside of the veneer using a small mirror, or you may be limited to looking for deficiencies that are more easily visible .

Clearances

On exterior stud walls, weep screeds and other base flashings should be held a minimum of 4 inches (102 mm) above grade or a minimum of 2 inches (51 mm) above paved surfaces such as driveways, patios, etc. This minimum can be reduced to 1 /2 inch (13 mm) if the paved surface is a walking surface supported by the same foundation supporting the wall.

On exterior stud walls where the AMSV continues down a concrete or CMU foundation wall, and where a weep screed is incorporated into the wall-to-foundation transition, at the bottom maintain minimum 2 inches (51 mm) clearance from grade, or 1 /2 inches (13 mm) clearance from a paved surface.

On exterior stud walls where the AMSV continues down a CMU foundation wall, with WRB and lath installed down to the weep screed at bottom, maintain a minimum 4 inches (102 mm) clearance from grade, or 2 inches (51 mm) clearance from a paved surface.

Where AMSV is applied over an exterior concrete or CMU wall, maintain 2 inches (51 mm) clearance from grade or 1 /2 inches (13 mm) from a paved surface. • Over an exterior concrete or CMU wall that is not enclosing conditioned space (e.g. landscape walls, pillars, columns, etc) maintain a minimum 2 inches (51 mm) clearance from grade or 1 /2 inches (13 mm) clearance from a paved surface

Water contact

MSV should not be directly exposed to discharge from downspouts or landscape irrigation sprinkler heads.