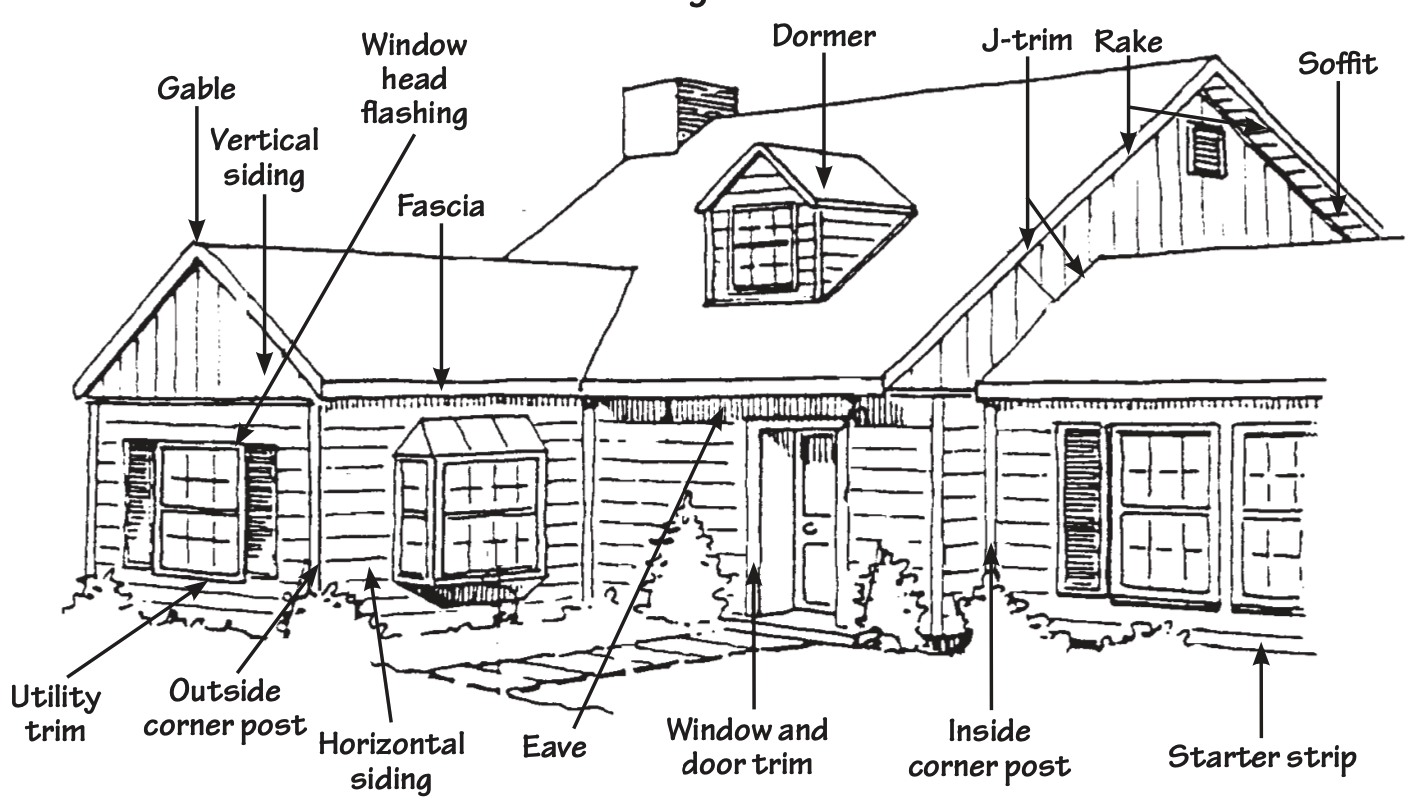

Vinyl Siding Installation Manual (Vinyl Siding Institute)

CLEARANCE

Vinyl siding should have ½-inch minimum clearance from roof-covering materials.

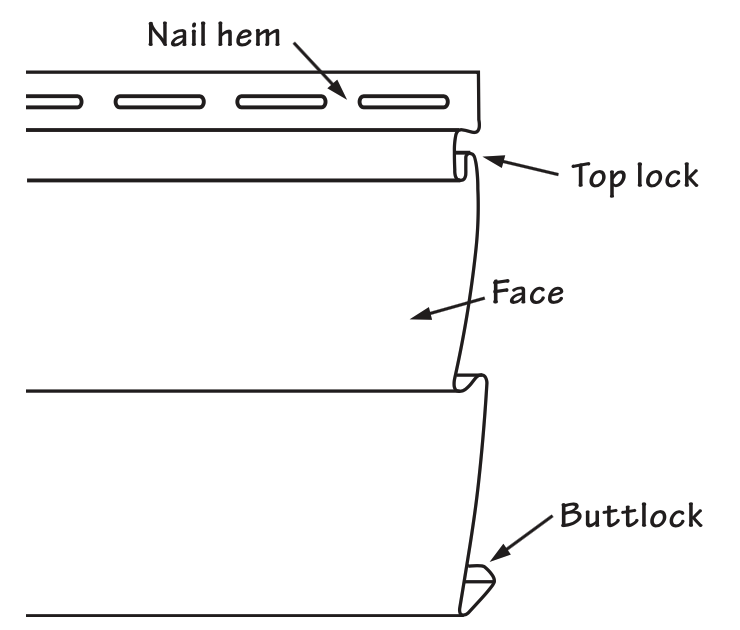

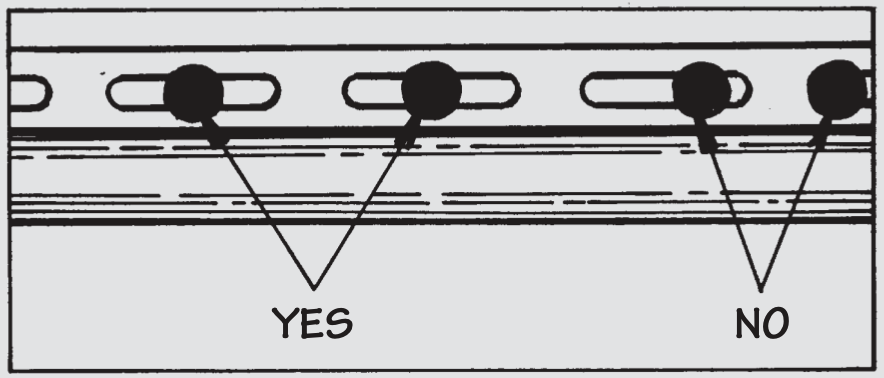

FASTENING

A major characteristic of vinyl siding is the large amount of expansion and contraction. Fastening methods need to take this movement into account.

- Nails should not be driven home, but left loose enough to accommodate thermal movement. The siding should hang from the nails, not be held in place by the pressure of the heads.

- Nails should be centered on slots to accommodate thermal movement.

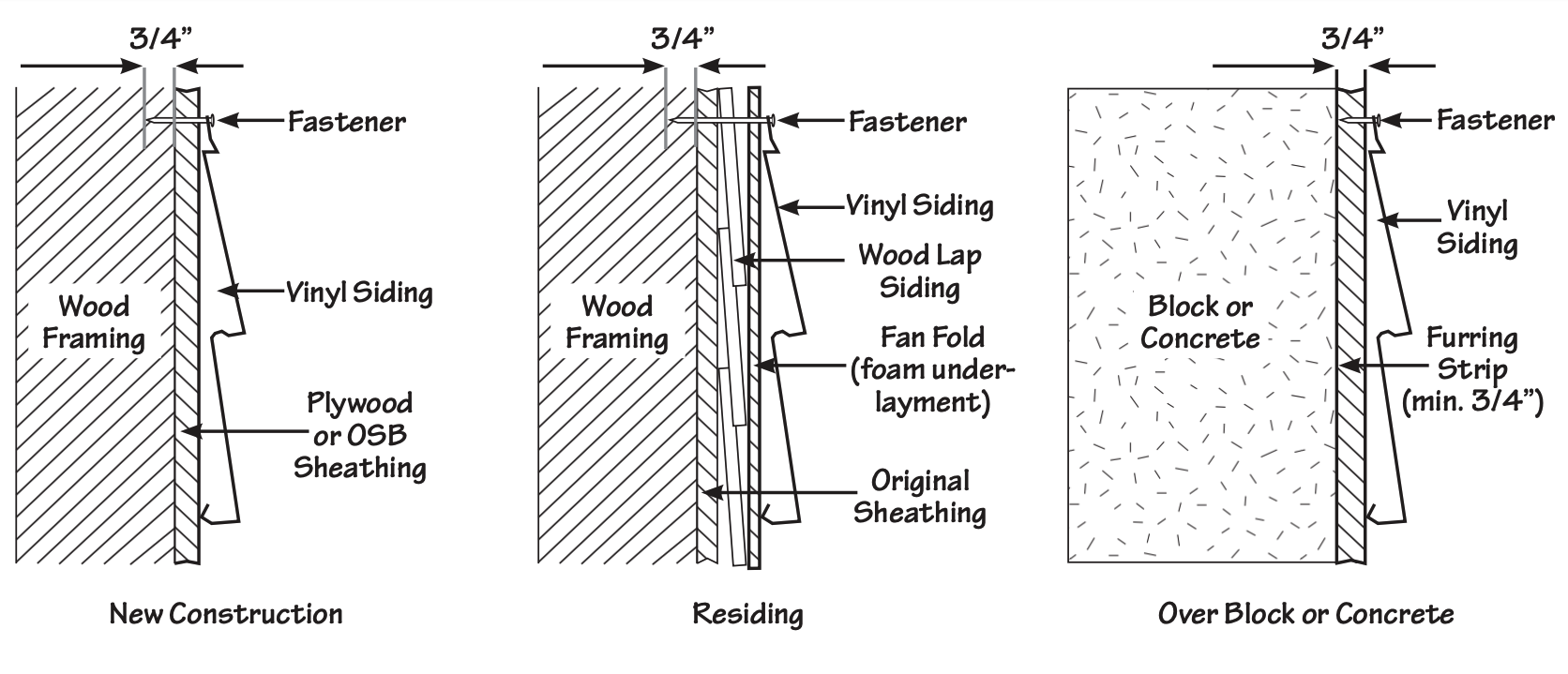

SUBSTRATE CONDITIONS

Vinyl Siding should installed over a water resistive barrier.

Installation requirements vary with substrates:

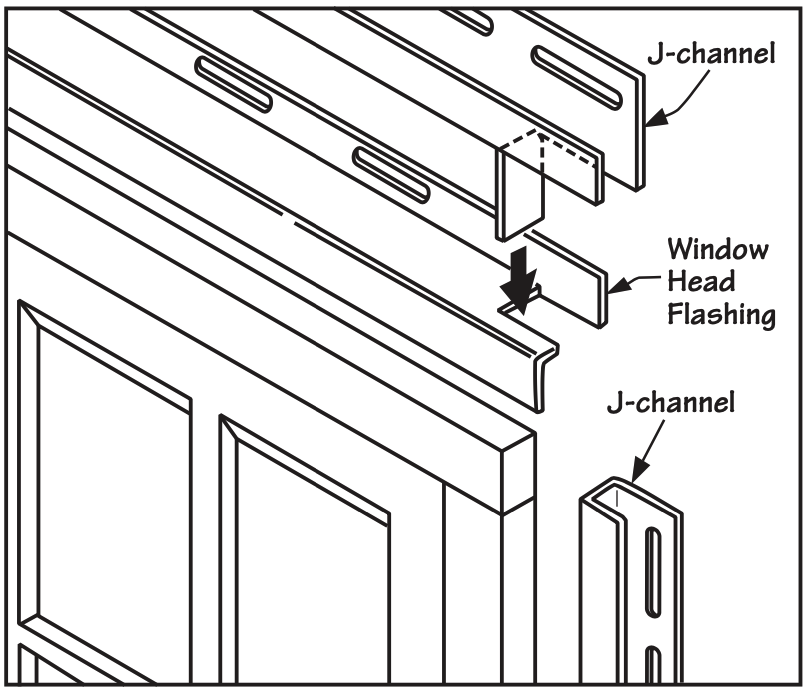

WINDOW & DOOR HEADS

Head flashing should be cut and bent at corners in a manner that will control runoff.

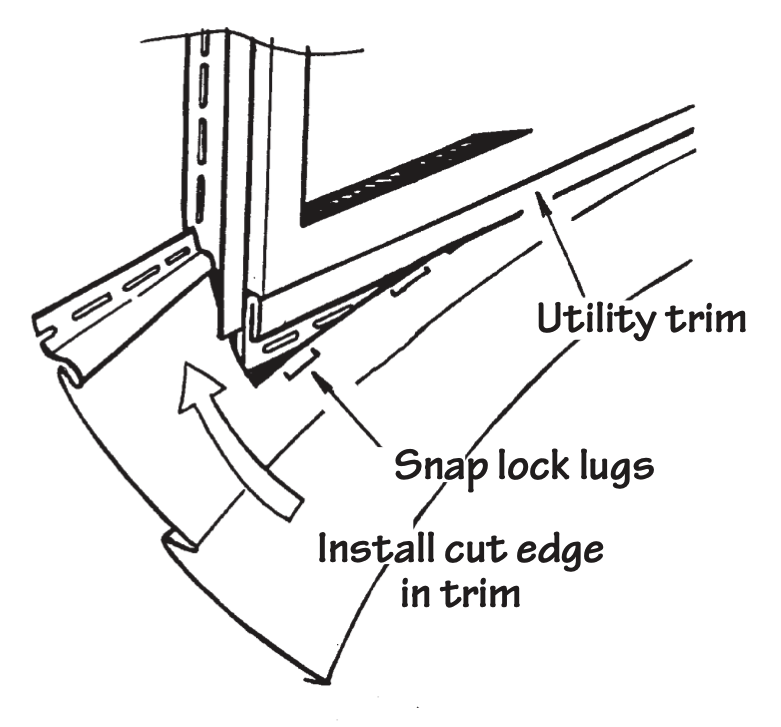

Utility trim should be installed beneath windows to accept the siding, which should have been punched with a special tool to allow the siding to lock into the snap lugs.

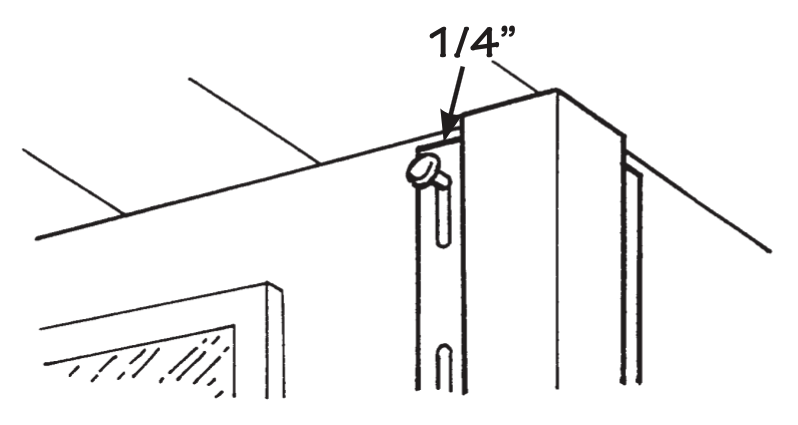

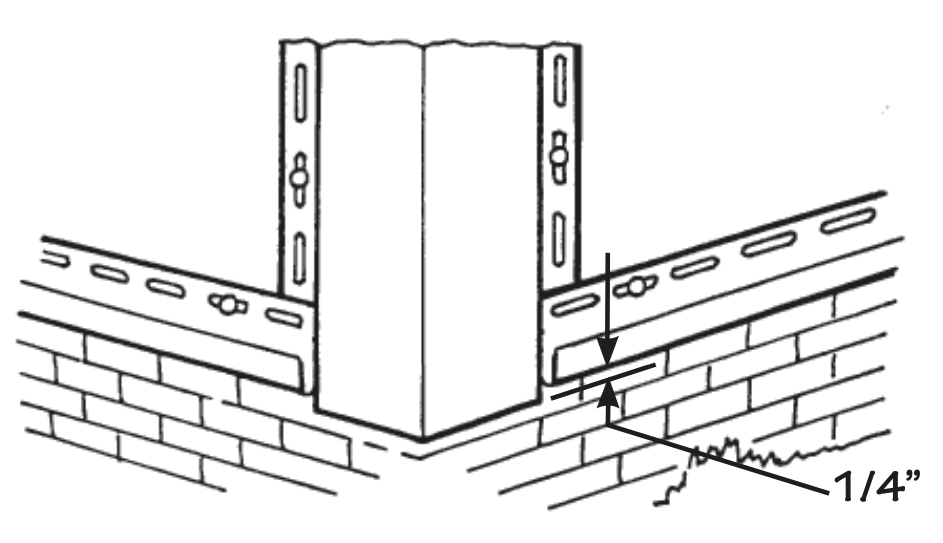

CORNERS

Expansion allowance should be anywhere lack of room to expand might cause damage. ¼-inch is typical.

FIELD PANELS

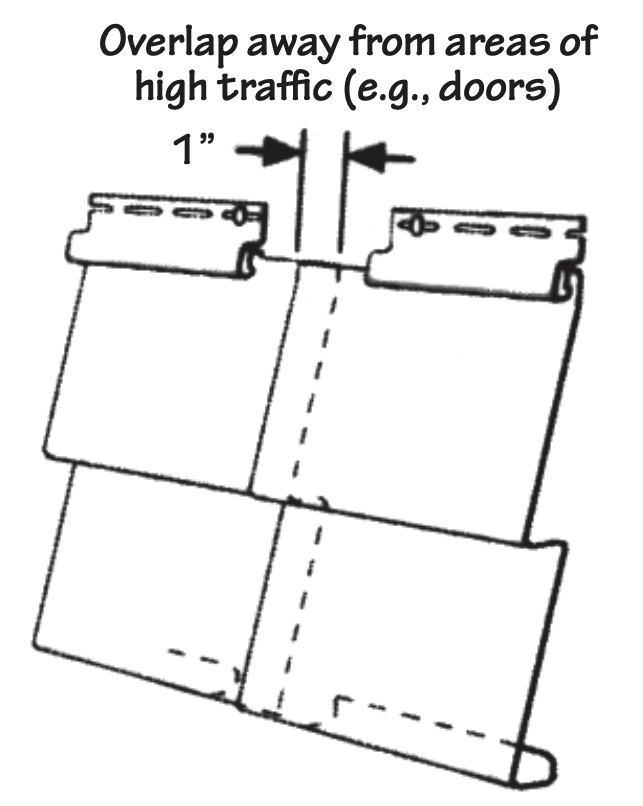

Panels in the same course should overlap an inch. This image shows an incorrect condition. Vertical joints should be separated from those in adjoining courses by at least 48 inches.

Using a tool like this one vinyl siding can be unzipped to view nailing and substrate.