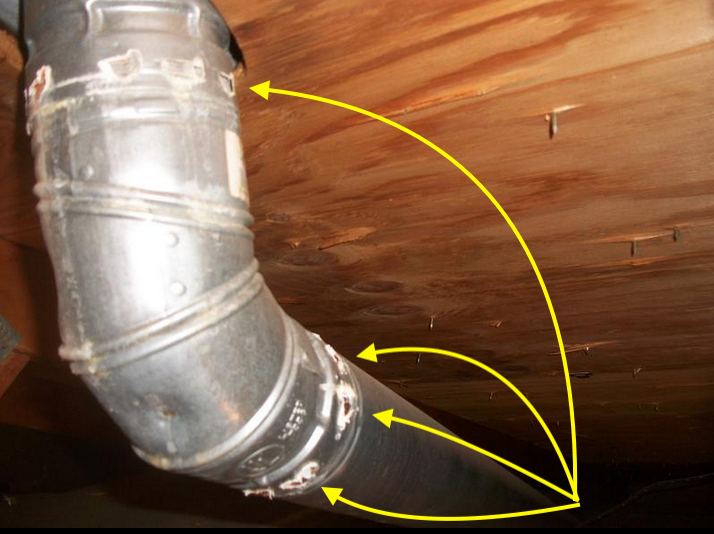

Zinc Oxide at vent connector joints

Due to inadequate combustion exhaust venting, sometimes combustion gases cool before they're expelled into the open air. This poor draft is usually caused by an excessively long (or too many bends in) the combustion vent. Cooling combustion gases condense on the inside of the galvanized steel vent where this condensation causes corrosion.

The first, kinda liquidy, gooey product of this corrosion is zinc hydroxide, which slides down the inside of the vent into the vent connector. It's not uncommon to see where some of it has leaked out onto the surface of the connector, typically at joints, but you may also see it on the tops of water heaters, furnaces, and boilers. Once it reaches the surface, the moisture evaporates, leaving a white, powdery residue that is zinc oxide.

Zinc hydroxide is a sign of inefficient or incomplete venting of the toxic products of combustion and when you see it, you should look for other signs indicating backdrafting.

On the water heater in the photo below, you can see heavy accumulations of zinc oxide, and warped plastic escutcheons, indicating backdrafting, another sign of poor draft.

Courtesy of Kyle Phillips