Inspecting Private Water Wells

To inspect wells, you'll need real training. Although this page will alert you to a few things that you can comment on, be sure to disclaim full inspection of the well and recommend that your client have a full well inspection performed by a qualified inspector or contractor. Depending on which jurisdiction the property is in, you may violate laws by performing a well inspection without the proper certifications.

Locating the Wellhead

In some states, when a permit for a well is issued a plot plan must be filed showing the location of the wellhead on the property. If in your state that information is available online, before you leave for the inspection, take the time to go to that website and look up the location of the wellhead. Sometimes they're buried under snow or debris and knowing where to start looking is a big advantage.

Well water quality testing

If you offer testing of well water for contaminants, you'll find a number of services online that will test water samples. You'll want to deal with a company that can recommend a course of action. When dealing with a company for the first time you should confirm their recommendations with your local health department. A few things to consider:

- Don't deal with a water treatment company. They're out to sell treatment systems. Deal with a company whose sole purpose is water testing and mitigation recommendations.

- Avoid do-it-yourself kits. They're not accurate or comprehensive.

- Confirm that shipping costs are included in the price.

- Know what contaminants should be tested for and don't pay extra for unnecessary testing.

- Local health departments may be able to suggest which contaminants to tets for.

Penalties for removing the sanitary cap: In some jurisdictions laws exist restricting the removal of sanitary caps. Penalties may include substantial fines. Before removing the cap to perform a static water level test, check to ensure that no restrictions apply.

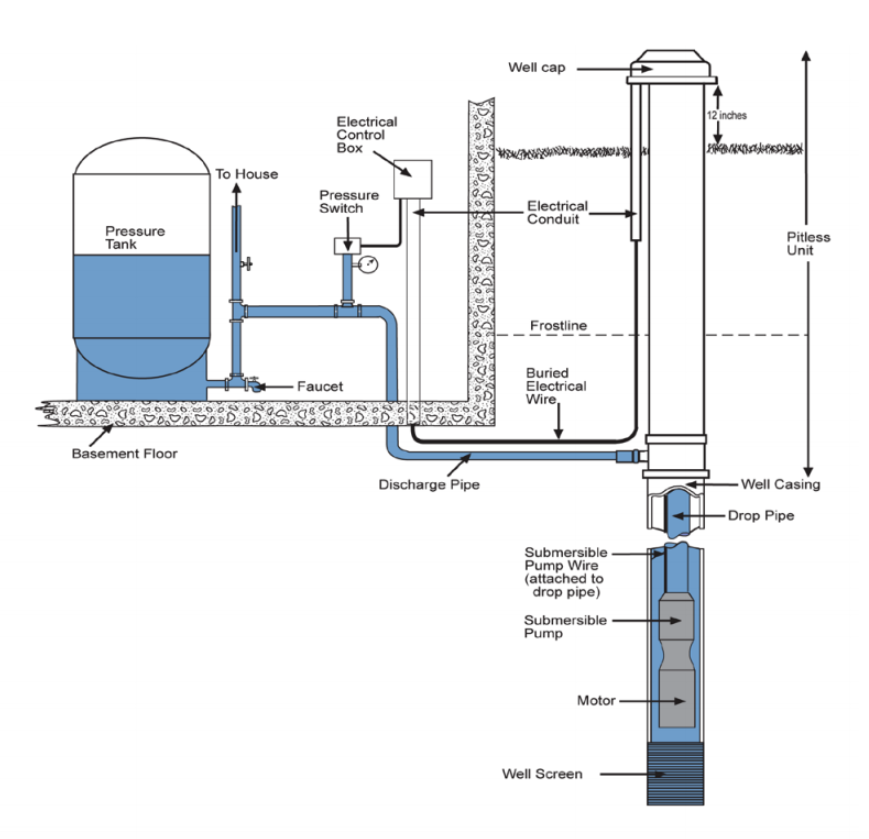

General Well Construction Guidelines:

- Well casing should protrude at least twelve inches above the ground level. (Check code for casing material requirements: plastic or steel)

- For wells drilled into rock (ledge, bedrock), the well casing should extend into solid, fresh, unweathered rock.

- The ground surface surrounding the wellhead should slope away to divert surface water from flowing or ponding around the well.

- A well cap should seal the top of the well casing. Venting holes should be screened to prevent insects from entering the well. (An unsealed or poorly sealed well can be a conduit for bacteria and surface water contamination).

- Well grout (code may specify cement and/or bentonite clay) should be used to seal around outside of the well casing to a depth of 10 to 20 feet starting near the ground surface.

- If you live in a cold climate the water line connecting the well to the house should be below the frost line (usually 4 to 6 feet). A “pitless adapter” is typically used for this connection to take water from the well to the home. This connection needs to watertight.

- The well casing should not be used as an electrical ground for the house because it may cause corrosion of the casing or well fittings through electrolysis.

- After installation or service work the well should be sanitized with a disinfection solution (usually chlorine). The solution should be left in the well and plumbing system for twelve or more hours before flushing.

- Well water should be tested after the sanitation process to determine if there are any water quality concerns present.