The CRAZE CRACKING

Do not call it a manufacturing defect!

"Functional damage" is an important term. It's used by shingles manufacturers and insurance companies to identify conditions that:

- Reduce the ability of a shingle to shed water, and

- Reduce the long-term lifespan of a shingle to less than that provided by the warrnty.

Craze cracking is not a manufacturing defect, it is low quality asphalt shingles performing as designed. If you report it as a manufacturing defect and your client files an insurance claim, that claim will be denied and your client will be unhappy with you. Unhappy clients are bad for business!

Craze cracking in asphalt shingles is random surface layer cracking. It's caused by forces similar to those that create shrinkage cracks in concrete (and mud): resistance to shrinkage.

Resistance to Shrinkage

Asphalt used in the manufacture of shingles has "volatile" compounds that are designed to keep shingles waterproof and flexible. These compounds evaporate slowly over shingle long-term service life.

Another ingredient used in asphalt shingles is filler made from powdered stone. The asphalt blend used for shingles may have up to 65% of asphalt replaced with filler without causing problems. When excessive amounts of filler are used, the rate at which volatile compounds evaporate increases. This increased evaporation rate results in shrinkage of the weather-facing surface layer at a rate faster than that of the underlying asphalt in the main body of the shingle. This difference in shrinkage rates creates tension in the surface layer that is relieved by cracking.

You may see it as soon as 5 years after installation. It's made worse by poor roof structure ventilation, which means a hotter roof, which means that volatile compounds evaporate at a faster rate.

Craze-cracking is NOT considered functional damage by either shingle manufacturers or insurance companies. It seldom turns into splitting (which is considered functional damage) before the shingle warranty has expired, or causes leaks, because cracks are in the surface layer only. In addition, underneath each craze-cracked shingle is another shingle, usually in much better shape since it hasn't been exposed to weather.

Eventually, cracks propagate through the mat to form splits. The roof is then at or near the end of its useful life.

THERMAL SPLITTING

Splitting Over Shingle Joints

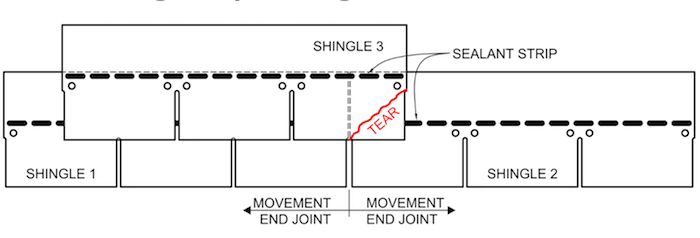

Shingle splitting due to temperature-related expansion and contraction is called thermal splitting. Thermal splitting typically happens where shingles bridge the joints in the underlying layer of shingles and it is connected to the strength of the sealant strip.

As shingles warm and expand, the joints between shingles in the same course become smaller. As shingles cool and shrink, the joints between them grow wider.

The shingles that bridge those underlying joints are shrinking, too, and these bridging shingles becoming increasingly stressed as the entire bonded-shingle assembly continues to shrink.

If this stress exceeds a critical point, one of two things will happen:

1. If the strength of the bond of the sealant strips exceeds the tensile strength of the shingles, the shingles bridging the joints will split, leaving just the underlauyment to resist leakage.

2. If the tensile strength of the shingles surpasses the strength of the sealant bonds, the bonds will fail, drastically lowering the wind resistance of the shingles. For this reason, shingle bonding always fails first above joints between underlying shingles.

No industry standards specify the minimum/maximum bond strength of shingle sealant strips.

Shingles may spit diagonally, in one direction or two.

WIND DAMAGE

Wind may break the sealant strip bond and bend tabs back, creating creases. The white line is a chalk mark made by an insurance adjuster denoting wind damage.