Skip to content

Floor Framing Overview

- Floor joists should overlap above intermediate supports a minimum of 12 inches and a maximum of 24 inches.

- Floor joists should have some type of anti-rotational device installed. In older homes, this was typically 1x4 X bracing installed approximately midspan. In newer homes it typically consists of blocks installed above supporting walls and beams.

- Floor joists and girders should have a minimum of 1.5 inches of bearing on wood and steel and 3 inches of bearing on concrete or masonry.

- Beam pockets in concrete and masonry walls should have a minimum of ½ inch air space on the sides of girders.

- Bottom plates of walls should be anchored to the tops of foundation walls.

- Look for signs of leakage and decay beneath sliding glass exterior doors, toilets, tubs, and sinks on the floor above.

- Look for the use of minimum 10d hanger nails (not 8d).The number should be marked on the head.

- Look for cut or damaged floor joists.

- Look for improperly notched or bored floor joists.

Main Floor Structure

- Floor joists, sheathing and support structure:

- Design/material/installation quality;

- Damage, deterioration, decay;

- Look for decay beneath exterior door thresholds and plumbing fixtures.

Framing Fasteners

- Metal connectors and their fasteners;

- Fasteners for almost all single metal connectors will be minimum 10d with the number marked on the nail head;

- Fasteners for almost all double and triple metal connectors will be minimum 16d vinyl-coated checker head nails;

- Simpson Strong-Tie page on fasteners for connectors.

Minimum Bearing

- On wood or metal: 1.5 inches

- On masonry: 3 inches

Allowable Notching and Boring

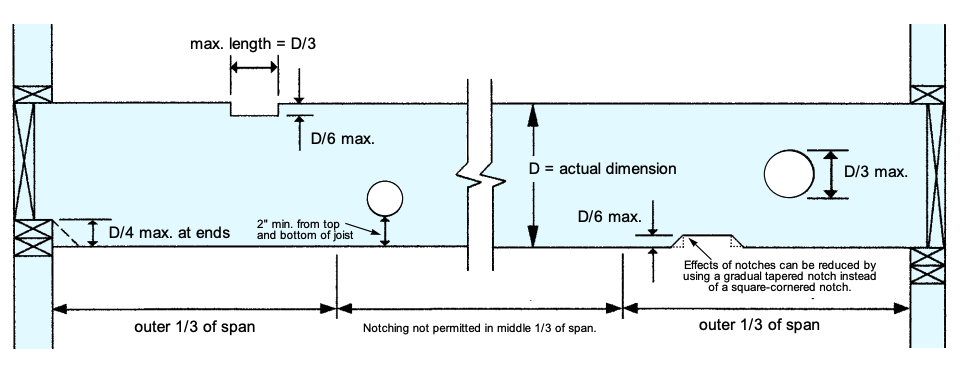

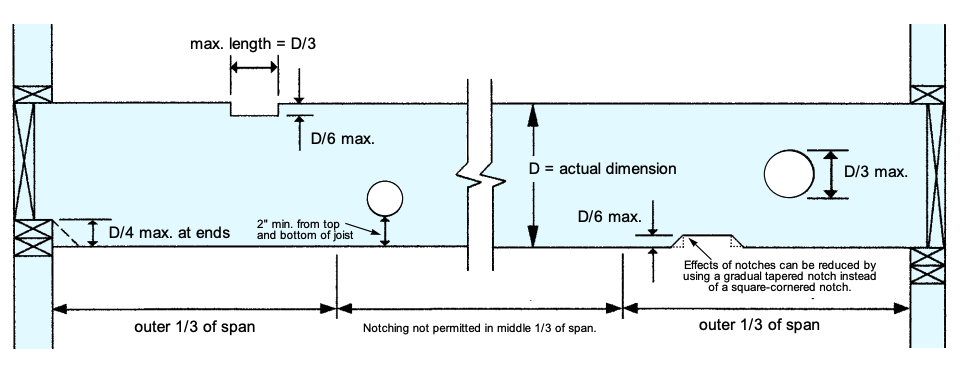

JOISTS R502.8.1

- Notches at the ends of joists cannot exceed 1/4 of the joist depth.

- Notches in top or bttm cannot exceed 1/6 the joist depth, and cannot be in middle 1/3 of joist

- Notches may not be located in middle 1/3 of span.

- Holes may not be located within 2" of the top or bottom and cannot exceed 1/3 the joist depth.

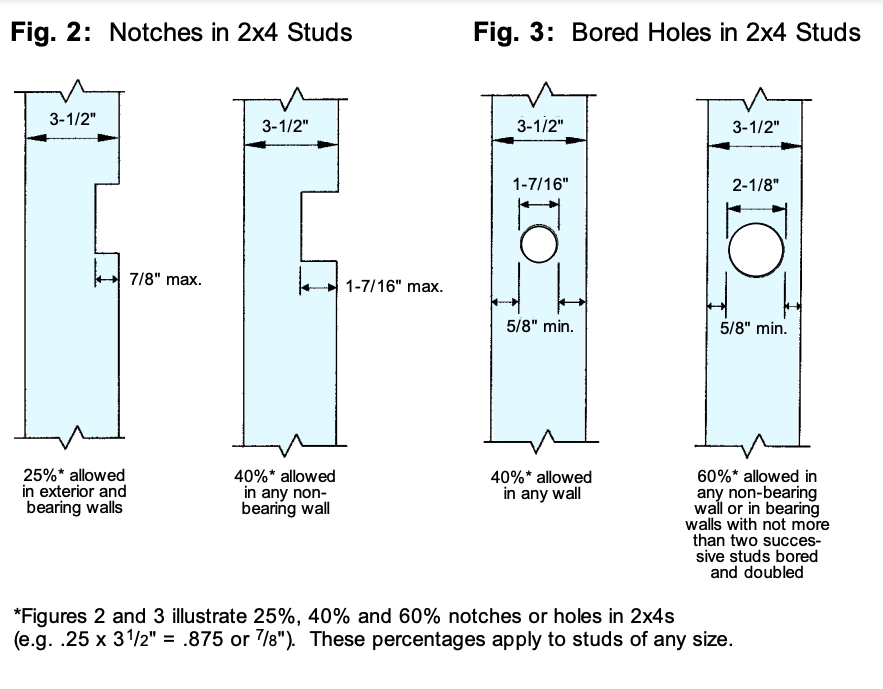

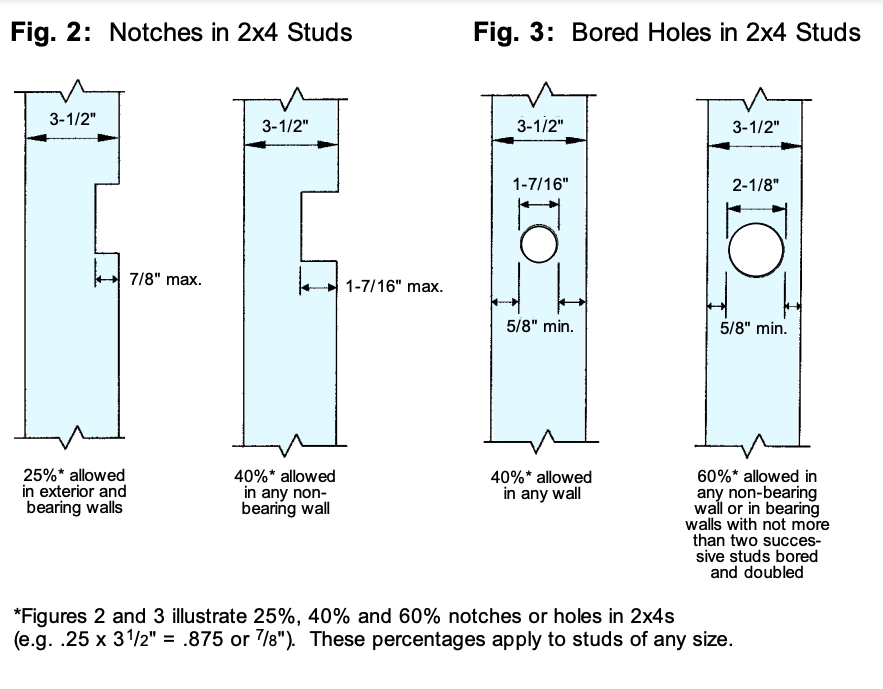

STUDS R602.6

NON-BEARING PARTITION WALLS

- Cutting or notching up to 40% of stud width is permitted.

- Boring holes up to 60% of stud width is permitted (also for a single, doubled- [sistered-] stud assembly).

OTHER (INCLUDING BEARING) STUD WALLS

- Bored holes cannot be closer than 5/8" to the edge of a stud.

- Any stud may be cut to a maximum of 25% (1/4) of its width.

- In exterior and/or load-bearing walls, holes cannot be bored a diameter greater than 40% of stud width.

- Top plates cut, drilled, or notched by more than 50% of their width must have a galvanized steel tie installed across the break/opening measuring minimum .054" x 1.5", fastened with at least 8- 16d nails each side of the break/opening.

- Bored holes in studs must not be located in the same as cuts or notches.

- If a hole is 40% to 60% of stud width, the stud must be doubled (sistered). No more than two adjacent studs can be doubled.

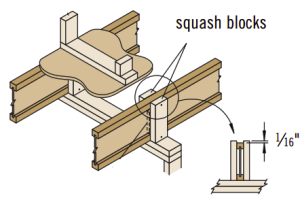

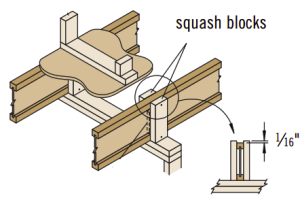

SQUASH BLOCKS

Two common reasons for squash blocks are:

- To carry load-bearing walls that stack above walls (or beams)

- To carry concentrated loads from above through the floor