Many homes are entirely sheathed in plywood or oriented strand board (OSB) during framing, however not every sheathed wall is a shear wall.

Shear walls are exterior or interior walls at key locations that are designed to resist extreme seismic or wind forces. The direction of the force resisted is parallel to the long axis of the wall.

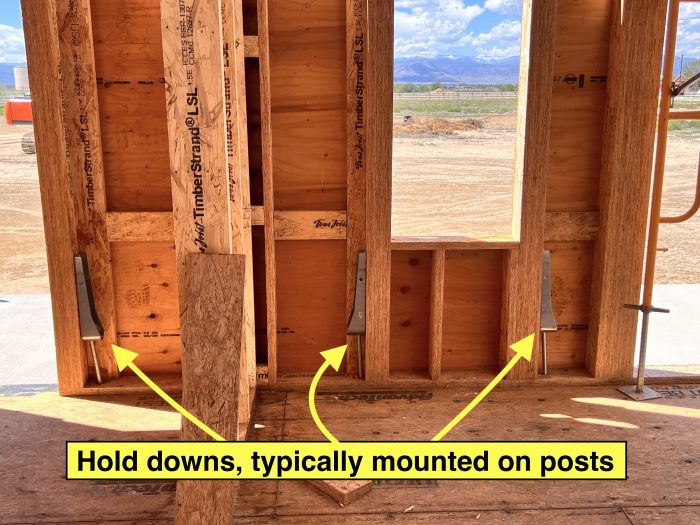

Shear walls require specialized hardware designed to anchor the walls securely to the foundation. This hardware may consist of anchor bolts spaced closely together (not shown), or hold downs.

Hold downs have specific bolt diameter requirements (typically 5/8" or bigger) and often must be mounted within a specific height range above the floor.

Nails through the panels into the studs are typically 8d gun nails. Ring shank may be specified. Occasionally 10d nails may be specified. Other fasteners (like yellow deck screws!) may not have adequate shear strength.

The nailing schedule may be 2” to 6" (or anything in between) along the panel edges, and 12" in the field (middle of each panel). Typical nailing for non-shear wall panels in most jurisdictions is 6" & 12".

Nails should not break the veneer, since that reduces the effective thickness of the shear panel. Nail guns in which the pressure is set too high can cause nails to be over-driven. When shooting into nominal lumber (not engineered lumber) stud hardness can vary, making pressure adjustment alone a difficult way to ensure that nails are not over-driven. A better way to control nailing is to use a flush nailing device that limits the stroke of the gun driver blade that strikes the head of the nail.