(Based on National Slate Association guidelines)

About Stone Slate

Slate is a natural stone formed 450 to 650 million years ago by the accumulation of marine sediments. The differences in color, density and durability are the result of the differences in its chemical and physical makeup, and the different types and magnitudes of forces that acted upon the slate as it was being formed.

Color

One concern with slate is its color-fastness, which refers to the long-term stability of the slate's natural color. Slate is classified as fading or unfading, according to its color stability. Fading slates may change to a different color over time. They may fade to a new shade of the same color, they may develop a streaked appearance, or they may slowly change to a different color. Color differences can be subtle, and similar-looking slates can have very different lifespans. Fading slates may change color at any time after installation. For this reason, accurate, long-term matching of existing slates can be difficult.

Density

The density of slate has a strong effect on its durability. Slate that was exposed to high pressure and temperatures during formation tends to be denser. Higher density makes slate less porous and less likely to absorb moisture. Moisture absorption is a major contributor to slate weathering and deterioration.

Inspecting Slate

Proper installation is key when you inspect a roof made from tiles that may last over 150 years. Underlayment, fasteners and flashing will almost always have shorter lifespans than slate. Don't be too quick to condemn a slate roof. Many problems can be fixed by a qualified contractor.

Failure to understand what to look for and where to look for it can cause inspectors to make major misses.

Walking Slate Roofs:

Don’t walk slate roofs.

Estimating Slate Lifespan:

Unless you are an experienced slate contractor you will not be able to visually identify the quarry from which a particular slate came nor be able to accurately estimate its remaining lifespan.

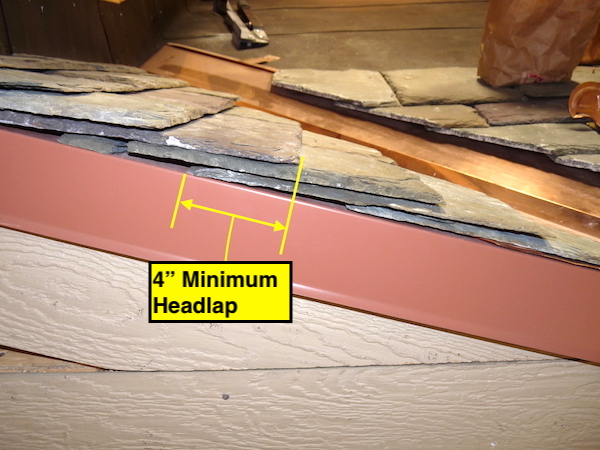

Headlap by Pitch:

Headlap of slate roofs is the amount by which slates in alternate courses overlap, not the amount by which slates in adjacent course overlap. Typical slate headlaps for different pitches are:

- Between 4&12 and 6&12: 4 inches

- Between 6&12 and 12&12: 3 inches

- Greater than 12&12: 2-3 inches

Signs of Aging:

Efflorescence, delamination (especially with biological growth growing between laminations), increased absorbance, and softening are all signs of aging slate.

Inspection concerns:

- Minimum slope. The IRC requires a minimum slope of 4&12. At roof pitches less than 4&12, slate is considered decorative and waterproof underlayment should be installed.

- Fasteners. They should be copper or hot-dipped galvanized. Lifespan of fasteners is almost always shorter than the lifespan of the slate. Electro-galvanized fasteners are a defective installation. Within 15 miles of the coast, fasteners should be copper.

- Flashing lifespan. Lead is good and so is copper, which has a lifespan of 60-70 years in high-wear areas like valleys. The lifespan of flashing can be extended by painting it. If it is pitted or has rusted through, or if it’s painted with tar (which means it has been leaking) it should be replaced. Flashing can be replaced without replacing the whole roof.

- Headwall flashing can be conventional.

- Sidewall flashing should be step-flashing.

- Penetration flashing at vents, chimneys and skylights should follow the rules for headwalls and sidewall flashing.

- Counter-flashing should be installed where it is appropriate.

- Bad installation can include:

- Inadequate headlap (the amount by which slates in alternate courses overlap).

- Interlay with felt between courses.

- Poor fastening, especially at gables and valleys where the installer sometimes must punch a new hole in a slate when a slate portion with a hole is cut off to make the slate fit.

- Lack of a cant strip or other means for lifting the butts of starter course slates into the same plane as field slates.

- Over-spaced snow guards can break slates.

- Bad repairs can include:

- Sealing with tar;

- Poor fastening methods

- Non-matching slates or other materials;

- Face-nailed slates, with nail heads sometimes covered with tar.

- Poor quality. Some foreign slates are meant for interior installation and sold not be exposed to cold weather.

- Occlusions. Brown streaking indicates occlusions; pockets of iron-rich minerals that will dissolve slowly and stain the roof.

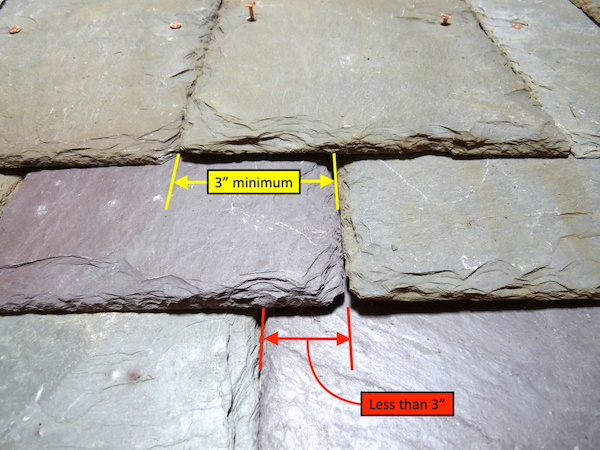

Slate should have 3-inch minimum sidelap